For Lewis, it is not only for internal use.

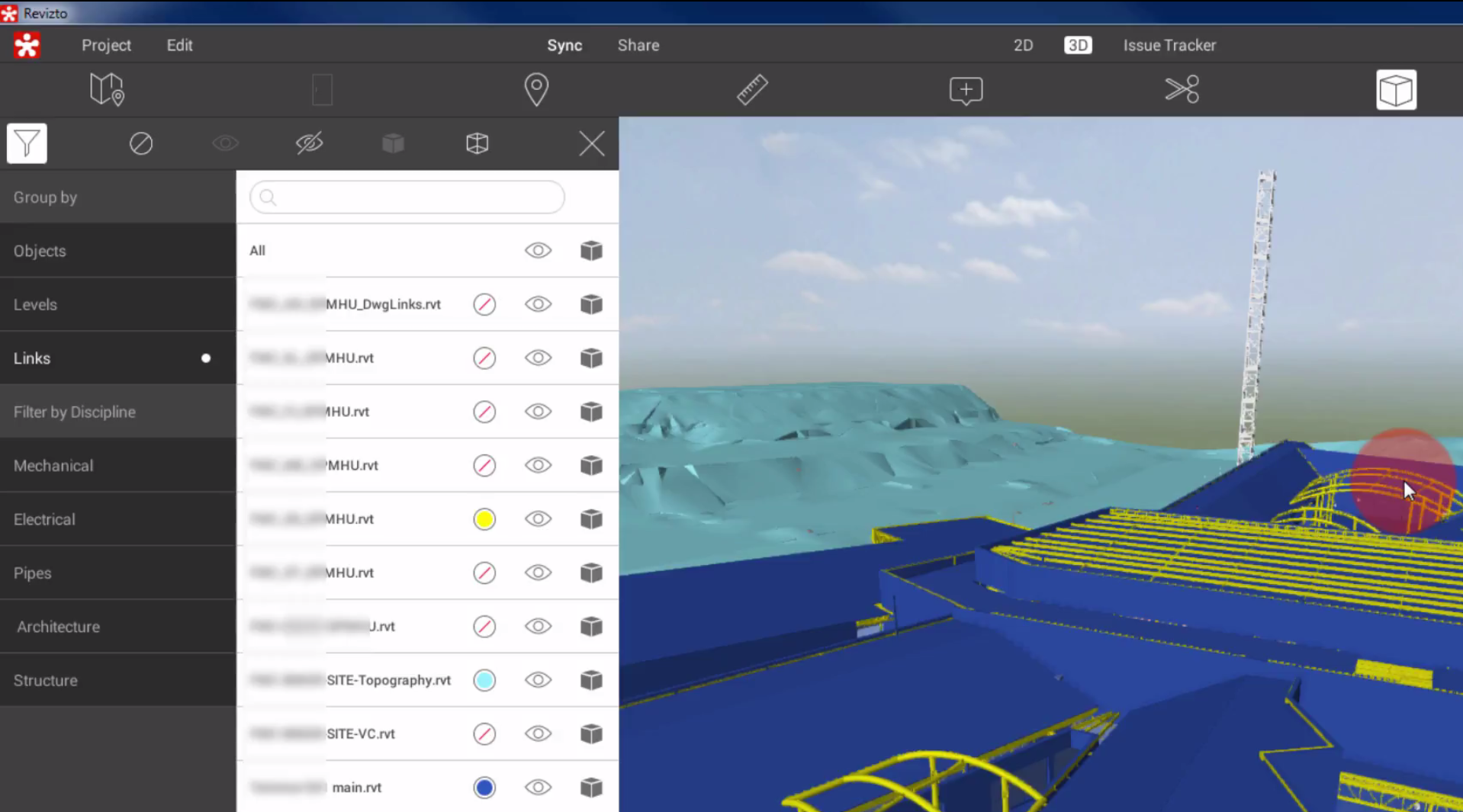

More importantly, Lewis values the ability to invite all project stakeholders to collaborate through Revizto. Being able to expose the 3D data from a particular discipline is key to avoiding multiple geometries from different models within the Revizto environment.” “Making sure that you understand what content is being shared from a model and that the view is set up inside your master project is really handy. When all those models go into Revizto, we have a model issue sheet that gives us specific information about the models and how they are coordinated – a real key advantage. We have a plain sheet that is available for general issues, which can then be assigned to people. “One of the key things that we like about Revizto is the ability to plug in a sheet when non-model issues are generated into the system, so that you don’t always need to have a model or drawing to generate an issue. Lewis was keen to share some peculiar tips from his experience with Revizto. As a result, the MEP coordination went through extreme measures, and managing these issues was nearly impossible… until we started using Revizto.” From a design point of view, the technicality of the MEP services for hospitals really exceeds our schemes, especially when taking into account the complications of dealing with medical gases or putting up backup systems in place. “Getting design sign-off from the hospital users, end users and the design team is a drawn-out process that needs to be done very precisely. Hospital construction projects are distinct Revizto helped them bring the entirety of issue management back into one place and keep all the drawings and models together. For Lewis’s team, comments on drawings and models were separate and people didn’t understand the relationship between them. Furthermore, managing the clash detection process from one tool to another was a considerable challenge. Managing architectural, structural, MEP and other issues concerning the model itself became a major problem for Lewis and his company. As a consequence, we ended up creating many different issue trackers and silos of issues within the tools bringing those into one place to handle them was difficult,” he said. Trying to coordinate the issues around both is a challenge. But the problem is that when this information is shared, the drawings are going in one direction and the models in another. “We had BIM tools, so we were generating models and drawings from those. His experience with Revizto started when his team had an ongoing challenge with process management, particularly during a hospital construction project.

Process management during Bouygues’s recent hospital construction project was a challenge – how did Revizto help? Lewis also reviews tender information and responds to all the pre-tender and post-contract requirements. He directly oversees the introduction of digital tools on to projects to make sure that information sharing between the project teams, including the design team, runs smoothly and accurately. Lewis Wenman’s job is to ensure that digital information management systems are correctly set up for projects and to align governance to meet the client’s information requirements. As part of a global and multi-faceted organisation, Bouygues Construction in the UK has direct access to best practice knowledge gleaned from an impressive back catalogue of major projects. Here we learn moreīouygues Construction’s entities in the UK have been operating in the country for over 20 years and have progressively grown their businesses in the building, infrastructure and industry sectors.

#REVIZTO HELP SOFTWARE#

Bouygues Construction implemented Revizto software during their Central London Hospital construction project when they experienced ongoing challenges with process management.

0 kommentar(er)

0 kommentar(er)